Hello my friends now I want to introduce about plastic. Did you know that plastic is was originally made from? Plastic is made from plastic seed.Plastic is one of the most used material in our everyday lives. It's low price makes it easier for people to afford and use, some examples are carrying and protecting materials. There are many advantages and disadvantages of plastics. And now I want to explain to you about history of plastic, how to make it, etc.

Thursday, November 14, 2013

Saturday, April 27, 2013

Manage Waste On Our School

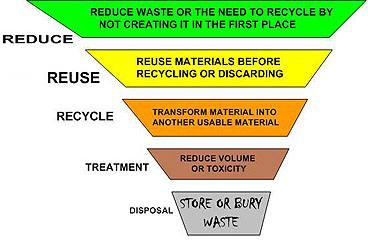

Recycling process is the guardian of nature preservation. Waste is not actually waste, but the resources of raw materials to the recycling process which produces humus or compost, fertilizer natural creation protector / soil builder. Continue turning recycled natural cycle is a key safety earth, are the responsibility of human beings in their respective communities. So that the waste is the responsibility of us all to recycle it into compost for the safety of the earth.

Recycling is the reuse of materials / goods that are not used to being another product. In addition to working to reduce the amount of waste that must be disposed of in landfills (landfill). Recycling of useful raw materials to meet the need for a product. And in terms of fuel use recycled can save the energy that must be removed to a factory.

The steps that need to be done to recycle: Separation. Separate the items / materials that can be recycled by the waste should be disposed of to landfill. Make sure the material is vacant and would be better if in a clean state. Storage. Save items / materials that have been separated was dried in a box / closed box depending on the type of goods, such as boxes for waste paper, bottles, etc.. If it will make compost, household waste pile composting on site. Delivery / Sales Items collected are sold to manufacturers who require such waste materials as raw materials sold to scavengers.

The garbage can be divided into 3 types, namely:

I. An Organic Garbage bins are not easily broken / obsolete is not a liquid and gas and is often referred to as dry waste. Inorganic garbage is divided into 2 parts:

a. Obsolete goods. Items that can be recycled back in clean and undamaged condition, has a high economic value. Example: Metal, iron, tin, plastic, rubber, etc..

b. Not an organic waste rotting stuff that really damaged and can not be traded so it has no economic value.

II. Organic waste bins are easily weathered / destroyed, instead of a liquid / gas and is often called the wet garbage. Organic waste consists of 3 parts:

a. Fresh organic waste, such as kitchen scraps, orchards, markets and restaurants.

b. By organic waste such as paper, cardboard, etc..

c. Organic waste recycling options for selected organic waste into compost that is fresh and soft and does not include harsh shaped like a soggy leftover vegetables, spices and remaining fruit.

III. Hazardous Waste garbage that requires special care to neutralize the pollution. This trash should be separated from the others so that the recycling process more quickly and produce products that are free of hazardous materials. Example: broken glass & glass, residual chemicals, batteries, bottles of insect repellent and nails.

COMPOST MAKING FROM OUR SCHOOL

Principles of composting organic waste material containing school + 75%. Composting process of adjusting to the availability of raw materials, which are not collected in large quantities at once, but little by little every day. This condition occurs in nature as the forest floor, where the organic remains fell onto the ground layer by layer until it becomes thick. Overhaul-fermentation process occurs from the bottom soil organisms spread to the pursuit of new materials that fall, followed by the formation of humus from the ground up anyway. Composting speed depends a.1. on the composition of raw materials, the comparison level C (high fibrous material) with N levels (types of legumes, manure, etc..). For optimal compost feedstock ratio C / N = + 30, the final result is humus or mature compost C / N = 12-15 Method and Tool Making compost is actually easy and simple, but because of its location in the yard of the house must be free of odor pollution , flies, dangerous animals and free of distractions chickens, dogs, cats, etc.. Moreover, the organic remains uncollected at once but gradually every day from kitchen waste and yard dirt.

For composting in the school yard, it takes two kinds of containers:1. Large container, container material and the site of the composting process, which is called "Compost" and placed in the garden in the shade.2. Small container in the form of a small plastic bucket with a lid, a temporary shelter kitchen organic waste.

Compost tool is the most practical and safe tool recommended STU Campbell (book "let It Rot", Storey Books, Vermont 1998) for use in the yard. Compost is made from 200 liter drums, the walls removed, and the walls of the base to be able to enter the middle dilobangi 3-4 inch PVC pipe, which also serves drainage. On a 5-cm PVC pipe made hole (drill) along the four sides. Mounted drum stand, given the prop 2-3 layers of bricks. PVC pipe is inserted into the hole basis, until the lower end touching the ground and the upper end of the drum stand up + 10 cm, through the midst of additional cap (can be made from plywood). Small bucket plastic bucket 5 l - 10 l is a lid, reserved for temporary shelter (1-2 days) residual organic orgasisa always placed in the kitchen and the kitchen is closed.

How it Works Composter (drums) placed in the yard in the shade. Should be made of plywood lid over the middle hollow where the advent of PVC pipe. Every time cleaning the yard, in the form of crumbling dirt leaves, grass fence pieces, etc. put into the composter, flattened, slightly compacted and sprinkled on top of a layer of old manure, compost or undercooked new, black fertile soil, and so on. as a starter enhancer N and soil organisms.

If it is too dry to moist and water were shut down to prevent from excessive rain, sun and pollution flies. To facilitate container near the composter supplied starter (cattle dung, etc.) are always closed. Every one or two days, a small bucket of dirt in the kitchen that is full, also included, flattened and coated starter.

So charging is done every time collected organic waste or feces new kitchen, to the composter is full, which takes 1 month - 2 months for a family is. Once full, closed and left behind and forth for 1 month + composting expected to be completed in the form of mature compost black, crumbs and smelling fresh. Composter emptied, its contents aerated, can directly be used alone or filtered (filter wire netting) wrapped and sold.

Occurred since the beginning of the composting process of organic matter incorporated, and propagate upward following the new organic materials. This will prompt a hot fermentation by thermophilic bacteria, as the temperature can rise within enclosed composter, which is also useful to kill seeds and weed pest. Composter is full and I are currently in the process pemasakkan, replaced composter II that had been prepared and later after I finished dokosongkan composter, be prepared to replace the composter II when it is full, and so on.

Organic materials in the school consists of leaves, paper, leftover side dishes, separated from the rest / non-organic waste. Kitchen waste is put into a small bucket and a non-organic accommodated in another container for disposal in the trash. Every time you include the rest of perishable organic kitchen (the rest of the side dishes), directly on top of a layer of fine sawdust sprinkled meetings. Then in the kitchen is always provided fine sawdust in a special container. Small bucket must always be sealed and usually within 1-2 days is full, then immediately taken to put in a garden composter, and sprinkled a layer on top of the starter.

Organic materials in the school consists of leaves, paper, leftover side dishes, separated from the rest / non-organic waste. Kitchen waste is put into a small bucket and a non-organic accommodated in another container for disposal in the trash. Every time you include the rest of perishable organic kitchen (the rest of the side dishes), directly on top of a layer of fine sawdust sprinkled meetings. Then in the kitchen is always provided fine sawdust in a special container. Small bucket must always be sealed and usually within 1-2 days is full, then immediately taken to put in a garden composter, and sprinkled a layer on top of the starter.

So as not to dirty plastic buckets, plastic bags should be coated so that the rest of perishable organic kitchen can fit securely and tightly. If it can be realized every household willing and able to recycle organic waste yard, and kitchen into compost, then dumped household waste is low and does not cause environmental pollution.

Lived waste disposed in the form of non-organic waste such as used goods plastic, tin, iron, etc and a little hard of organic waste such as scrap items of wood, bamboo, cardboard, hard rind and most of these items can be exploited through scavengers. In this way almost all the organic material that can be recycled urban waste problem can be solved in a healthy and supportive safety earth.

One thing, where people have not managed to connect the disconnected recycling cycle, namely the problem of impurities (taeces) and human urine because it is still hampered by cultural issues.

Recycling is the reuse of materials / goods that are not used to being another product. In addition to working to reduce the amount of waste that must be disposed of in landfills (landfill). Recycling of useful raw materials to meet the need for a product. And in terms of fuel use recycled can save the energy that must be removed to a factory.

The steps that need to be done to recycle: Separation. Separate the items / materials that can be recycled by the waste should be disposed of to landfill. Make sure the material is vacant and would be better if in a clean state. Storage. Save items / materials that have been separated was dried in a box / closed box depending on the type of goods, such as boxes for waste paper, bottles, etc.. If it will make compost, household waste pile composting on site. Delivery / Sales Items collected are sold to manufacturers who require such waste materials as raw materials sold to scavengers.

The garbage can be divided into 3 types, namely:

I. An Organic Garbage bins are not easily broken / obsolete is not a liquid and gas and is often referred to as dry waste. Inorganic garbage is divided into 2 parts:

a. Obsolete goods. Items that can be recycled back in clean and undamaged condition, has a high economic value. Example: Metal, iron, tin, plastic, rubber, etc..

b. Not an organic waste rotting stuff that really damaged and can not be traded so it has no economic value.

II. Organic waste bins are easily weathered / destroyed, instead of a liquid / gas and is often called the wet garbage. Organic waste consists of 3 parts:

a. Fresh organic waste, such as kitchen scraps, orchards, markets and restaurants.

b. By organic waste such as paper, cardboard, etc..

c. Organic waste recycling options for selected organic waste into compost that is fresh and soft and does not include harsh shaped like a soggy leftover vegetables, spices and remaining fruit.

III. Hazardous Waste garbage that requires special care to neutralize the pollution. This trash should be separated from the others so that the recycling process more quickly and produce products that are free of hazardous materials. Example: broken glass & glass, residual chemicals, batteries, bottles of insect repellent and nails.

COMPOST MAKING FROM OUR SCHOOL

Principles of composting organic waste material containing school + 75%. Composting process of adjusting to the availability of raw materials, which are not collected in large quantities at once, but little by little every day. This condition occurs in nature as the forest floor, where the organic remains fell onto the ground layer by layer until it becomes thick. Overhaul-fermentation process occurs from the bottom soil organisms spread to the pursuit of new materials that fall, followed by the formation of humus from the ground up anyway. Composting speed depends a.1. on the composition of raw materials, the comparison level C (high fibrous material) with N levels (types of legumes, manure, etc..). For optimal compost feedstock ratio C / N = + 30, the final result is humus or mature compost C / N = 12-15 Method and Tool Making compost is actually easy and simple, but because of its location in the yard of the house must be free of odor pollution , flies, dangerous animals and free of distractions chickens, dogs, cats, etc.. Moreover, the organic remains uncollected at once but gradually every day from kitchen waste and yard dirt.

For composting in the school yard, it takes two kinds of containers:1. Large container, container material and the site of the composting process, which is called "Compost" and placed in the garden in the shade.2. Small container in the form of a small plastic bucket with a lid, a temporary shelter kitchen organic waste.

Compost tool is the most practical and safe tool recommended STU Campbell (book "let It Rot", Storey Books, Vermont 1998) for use in the yard. Compost is made from 200 liter drums, the walls removed, and the walls of the base to be able to enter the middle dilobangi 3-4 inch PVC pipe, which also serves drainage. On a 5-cm PVC pipe made hole (drill) along the four sides. Mounted drum stand, given the prop 2-3 layers of bricks. PVC pipe is inserted into the hole basis, until the lower end touching the ground and the upper end of the drum stand up + 10 cm, through the midst of additional cap (can be made from plywood). Small bucket plastic bucket 5 l - 10 l is a lid, reserved for temporary shelter (1-2 days) residual organic orgasisa always placed in the kitchen and the kitchen is closed.

How it Works Composter (drums) placed in the yard in the shade. Should be made of plywood lid over the middle hollow where the advent of PVC pipe. Every time cleaning the yard, in the form of crumbling dirt leaves, grass fence pieces, etc. put into the composter, flattened, slightly compacted and sprinkled on top of a layer of old manure, compost or undercooked new, black fertile soil, and so on. as a starter enhancer N and soil organisms.

If it is too dry to moist and water were shut down to prevent from excessive rain, sun and pollution flies. To facilitate container near the composter supplied starter (cattle dung, etc.) are always closed. Every one or two days, a small bucket of dirt in the kitchen that is full, also included, flattened and coated starter.

So charging is done every time collected organic waste or feces new kitchen, to the composter is full, which takes 1 month - 2 months for a family is. Once full, closed and left behind and forth for 1 month + composting expected to be completed in the form of mature compost black, crumbs and smelling fresh. Composter emptied, its contents aerated, can directly be used alone or filtered (filter wire netting) wrapped and sold.

Occurred since the beginning of the composting process of organic matter incorporated, and propagate upward following the new organic materials. This will prompt a hot fermentation by thermophilic bacteria, as the temperature can rise within enclosed composter, which is also useful to kill seeds and weed pest. Composter is full and I are currently in the process pemasakkan, replaced composter II that had been prepared and later after I finished dokosongkan composter, be prepared to replace the composter II when it is full, and so on.

Organic materials in the school consists of leaves, paper, leftover side dishes, separated from the rest / non-organic waste. Kitchen waste is put into a small bucket and a non-organic accommodated in another container for disposal in the trash. Every time you include the rest of perishable organic kitchen (the rest of the side dishes), directly on top of a layer of fine sawdust sprinkled meetings. Then in the kitchen is always provided fine sawdust in a special container. Small bucket must always be sealed and usually within 1-2 days is full, then immediately taken to put in a garden composter, and sprinkled a layer on top of the starter.

Organic materials in the school consists of leaves, paper, leftover side dishes, separated from the rest / non-organic waste. Kitchen waste is put into a small bucket and a non-organic accommodated in another container for disposal in the trash. Every time you include the rest of perishable organic kitchen (the rest of the side dishes), directly on top of a layer of fine sawdust sprinkled meetings. Then in the kitchen is always provided fine sawdust in a special container. Small bucket must always be sealed and usually within 1-2 days is full, then immediately taken to put in a garden composter, and sprinkled a layer on top of the starter.So as not to dirty plastic buckets, plastic bags should be coated so that the rest of perishable organic kitchen can fit securely and tightly. If it can be realized every household willing and able to recycle organic waste yard, and kitchen into compost, then dumped household waste is low and does not cause environmental pollution.

Lived waste disposed in the form of non-organic waste such as used goods plastic, tin, iron, etc and a little hard of organic waste such as scrap items of wood, bamboo, cardboard, hard rind and most of these items can be exploited through scavengers. In this way almost all the organic material that can be recycled urban waste problem can be solved in a healthy and supportive safety earth.

One thing, where people have not managed to connect the disconnected recycling cycle, namely the problem of impurities (taeces) and human urine because it is still hampered by cultural issues.

Wednesday, April 17, 2013

Polystyrene

Polystyrene (PS) is a synthetic aromatic polymer made from the monomer styrene, a liquid petrochemical. Polystyrene can be rigid or foamed. General purpose is hard and brittle. It is a cheaper resin per unit weight. It is a rather poor barrier to oxygen and water vapor and has relatively low melting point.Polystyrene is one of the most widely used plastics, the scale of its production being several billion kilograms per year.Polystyrene can be naturally transparent, but can be colored with colorants. Uses include protective packaging (such as packing peanuts and CD and DVD cases), containers (such as "clamshells"), lids, bottles, trays, tumblers, and disposable cutlery.

As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature. It becomes rigid again when cooled. This temperature behavior is exploited for extrusion, and also for molding and vacuum forming, since it can be cast into molds with fine detail.

It is very slow to biodegrade and therefore a focus of controversy, since it is often abundant as a form of litter in the outdoor environment, particularly along shores and waterways especially in its foam form.

Polystyrene was found in 1839 by Eduard Simon,an apothecary in Berlin. From storax, the resin of the Turkish sweetgum tree Liquidambar orientalis, he distilled an oily substance, a monomer that he named styrol. Several days later, Simon found that the styrol had thickened, presumably from oxidation, into a jelly he dubbed styrol oxide ("Styroloxyd"). By 1845 English chemist John Blyth and German chemist August Wilhelm von Hofmann showed that the same transformation of styrol took place in the absence of oxygen. They called their substance metastyrol. Analysis later showed that it was chemically identical to Styroloxyd. In 1866 Marcelin Berthelot correctly identified the formation of metastyrol/Styroloxyd from styrol as a polymerization process. About 80 years later it was realized that heating of styrol starts a chain reaction that produces macromolecules, following the thesis of German organic chemist Hermann Staudinger (1881–1965). This eventually led to the substance receiving its present name, polystyrene.

The company I. G. Farben began manufacturing polystyrene in Ludwigshafen, about 1931, hoping it would be a suitable replacement for die-cast zinc in many applications. Success was achieved when they developed a reactor vessel that extruded polystyrene through a heated tube and cutter, producing polystyrene in pellet form.

In 1941, Dow Chemical invented a Styrofoam process.Before 1949, the chemical engineer Fritz Stastny (1908–1985) developed pre-expanded PS beads by incorporating aliphatic hydrocarbons, such as pentane. These beads are the raw material for moulding parts or extruding sheets. BASF and Stastny applied for a patent that was issued in 1949. The moulding process was demonstrated at the Kunststoff Messe 1952 in Düsseldorf. Products were named Styropor.The crystal structure of isotactic polystyrene was reported by Giulio Natta.

In 1954, the Koppers Company, Inc. in Pittsburgh, Pennsylvania, developed expanded polystyrene (EPS) foam.In 1960, Dart Container, the largest manufacturer of foam cups, shipped their first order.In 1988, the first U.S. ban of general polystyrene foam was enacted in Berkeley, California.

This Picture is about yogurt container

This Picture is about yogurt container

As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature. It becomes rigid again when cooled. This temperature behavior is exploited for extrusion, and also for molding and vacuum forming, since it can be cast into molds with fine detail.

It is very slow to biodegrade and therefore a focus of controversy, since it is often abundant as a form of litter in the outdoor environment, particularly along shores and waterways especially in its foam form.

Polystyrene was found in 1839 by Eduard Simon,an apothecary in Berlin. From storax, the resin of the Turkish sweetgum tree Liquidambar orientalis, he distilled an oily substance, a monomer that he named styrol. Several days later, Simon found that the styrol had thickened, presumably from oxidation, into a jelly he dubbed styrol oxide ("Styroloxyd"). By 1845 English chemist John Blyth and German chemist August Wilhelm von Hofmann showed that the same transformation of styrol took place in the absence of oxygen. They called their substance metastyrol. Analysis later showed that it was chemically identical to Styroloxyd. In 1866 Marcelin Berthelot correctly identified the formation of metastyrol/Styroloxyd from styrol as a polymerization process. About 80 years later it was realized that heating of styrol starts a chain reaction that produces macromolecules, following the thesis of German organic chemist Hermann Staudinger (1881–1965). This eventually led to the substance receiving its present name, polystyrene.

The company I. G. Farben began manufacturing polystyrene in Ludwigshafen, about 1931, hoping it would be a suitable replacement for die-cast zinc in many applications. Success was achieved when they developed a reactor vessel that extruded polystyrene through a heated tube and cutter, producing polystyrene in pellet form.

In 1941, Dow Chemical invented a Styrofoam process.Before 1949, the chemical engineer Fritz Stastny (1908–1985) developed pre-expanded PS beads by incorporating aliphatic hydrocarbons, such as pentane. These beads are the raw material for moulding parts or extruding sheets. BASF and Stastny applied for a patent that was issued in 1949. The moulding process was demonstrated at the Kunststoff Messe 1952 in Düsseldorf. Products were named Styropor.The crystal structure of isotactic polystyrene was reported by Giulio Natta.

In 1954, the Koppers Company, Inc. in Pittsburgh, Pennsylvania, developed expanded polystyrene (EPS) foam.In 1960, Dart Container, the largest manufacturer of foam cups, shipped their first order.In 1988, the first U.S. ban of general polystyrene foam was enacted in Berkeley, California.

This Picture is about yogurt container

This Picture is about yogurt container

Thursday, April 11, 2013

Melamine resin with Apllication

Melamine resin or melamine formaldehyde (melamine) is a hard thermosetting plastic material made from melamine and formaldehyde by polymerization. In its butylated form, it is dissolved in n-butanol and xylene. It is used to cross-link with alkyd, epoxy, acrylic, and polyester resins, which used in surface coatings. There are many types, varying from very slow to very fast curing. It was discovered by William F. Talbot.

Melamine resin is often used in kitchen utensils and plates (like Melmac). Melamine resin utensils and bowls are not microwave safe. As with all thermosetting materials, melamine resin cannot be melted. Therefore, cannot be recycled through melting.

During the late 1950s and 1960s melamine tableware became highly fashionable. Aided crucially by the stylish modern designs of A. H. Woodfull and the Product Design Unit of British Industrial Plastics, it was thought to threaten the dominant position of ceramics in the market. The tendency of melamine cups and plates to stain and scratch led sales to decline in the late 1960s, however, and eventually the material became largely restricted to the camping and nursery market.

This picture is melamine plate

Melamine resin is often used in kitchen utensils and plates (like Melmac). Melamine resin utensils and bowls are not microwave safe. As with all thermosetting materials, melamine resin cannot be melted. Therefore, cannot be recycled through melting.

During the late 1950s and 1960s melamine tableware became highly fashionable. Aided crucially by the stylish modern designs of A. H. Woodfull and the Product Design Unit of British Industrial Plastics, it was thought to threaten the dominant position of ceramics in the market. The tendency of melamine cups and plates to stain and scratch led sales to decline in the late 1960s, however, and eventually the material became largely restricted to the camping and nursery market.

This picture is melamine plate

Wednesday, April 3, 2013

LDPE (Low density polyethylene), chemical and apllication

Low-density polyethylene (LDPE) is a thermoplastic made from the monomer ethylene. It was the first grade of polyethylene, produced in 1933 by Imperial Chemical Industries (ICI) using a high pressure process via free radical polymerization. Its manufacture employs the same method today. The EPA estimates 5.7% of LDPE (recycling number 4) is recycled. Despite competition from more modern polymers, LDPE continues to be an important plastic grade. In 2009 the worldwide LDPE market reached a volume of US$22.2 billion (15.9 billion Euro).

LDPE is widely used for manufacturing various containers, dispensing bottles, wash bottles, tubing, plastic bags for computer components, and various molded laboratory equipment. Its most common use is in plastic bags. Other products made from it include:

LDPE is widely used for manufacturing various containers, dispensing bottles, wash bottles, tubing, plastic bags for computer components, and various molded laboratory equipment. Its most common use is in plastic bags. Other products made from it include:

- Trays and general purpose containers

- Corrosion-resistant work surfaces

- Parts that need to be weldable and machinable

- Parts that require flexibility, for which it serves very well

- Very soft and pliable parts such as snap-on lids

- Six pack rings

- Juice and milk cartons are made of liquid packaging board, a laminate of paperboard and LDPE (as the water-proof inner and outer layer), and often with of a layer of aluminum foil (thus becoming aseptic packaging).

- Parts of computer hardware, such as hard disk drives, screen cards, and optical disc drives

- Playground slides

- Plastic wraps

Chemical resistance

- Excellent resistance (no attack) to dilute and concentrated acids, alcohols, bases and esters

- Good resistance (minor attack) to aldehydes, ketones and vegetable oils

- Limited resistance (moderate attack suitable for short-term use only) to aliphatic and aromatic hydrocarbons, mineral oils, and oxidizing agents

- Poor resistance, and not recommended for use with Halogenated hydrocarbons.

This picture is ID code of LDPE (Low density polyethylene)

Tuesday, March 26, 2013

THE ZOO

One day, the zoo was crouded. Because at the day is sunday and the zoo has events. Many family goes to the zoo. When people come to the zoo, the old lion was sleeping.

"Lions ought not to behave like that!" the young lion said to himself, so he roared at all the visitors and tried to break the bars of the den.

At three o'clock a man brought a big piece of meat and put it in the old lion's den. Then, he put a bag of nuts and two bananas in the young lion's den.

The young lion was very surprised. "I don't understand this." he said to the old lion. "I behave like a real lion, while you lie there and do nothing and look what happens!"

"Okay, I'll behave like a real lion" said the old lion, and the old lion was roared to all visitors. Many people came closer to their cage. So their visitor was very happy and many visitor buy some meat for it. And the lion was happy.

"Lions ought not to behave like that!" the young lion said to himself, so he roared at all the visitors and tried to break the bars of the den.

At three o'clock a man brought a big piece of meat and put it in the old lion's den. Then, he put a bag of nuts and two bananas in the young lion's den.

The young lion was very surprised. "I don't understand this." he said to the old lion. "I behave like a real lion, while you lie there and do nothing and look what happens!"

"Okay, I'll behave like a real lion" said the old lion, and the old lion was roared to all visitors. Many people came closer to their cage. So their visitor was very happy and many visitor buy some meat for it. And the lion was happy.

Thursday, March 21, 2013

HDPE (High Density Polyethylene) and application

High-density polyethylene (HDPE) is a polyethylene thermoplastic made from petroleum. HDPE (High-density polyethylene) is commonly used in the production of plastic bottles, corrosion-resistant piping, geomembranes, and plastic lumber.It takes the equivalent of 1.75 kilograms of petroleum (in energy and raw materials) to make one kilogram of HDPE. HDPE is commonly recycled, and has the number "2" as its recycling symbol.In 2007, the global HDPE market reached a volume of more than 30 million tons.

HDPE is known for its large strength to density ratio.The mass density of high-density polyethylene can range from 0.93 to 0.97 g/cm3. Although the density of HDPE is only marginally higher than that of low-density polyethylene (LDPE), HDPE has little branching, giving it stronger intermolecular forces and tensile strength than LDPE. The difference in strength exceeds the difference in density, giving HDPE a higher specific strength.It is also harder and more opaque and can withstand higher temperatures (120 °C/ 248 °F for short periods, 110 °C /230 °F continuously). High-density polyethylene (HDPE) unlike polypropylene, which cannot withstand normally required autoclaving conditions. The lack of branching is ensured by an appropriate choice of catalyst (e.g., Ziegler-Natta catalysts) and reaction conditions. HDPE contains the chemical elements carbon and hydrogen.

HDPE has a wide variety of applications because it is resistant with many different solvent for example:

- Arena Board (puck board)

- Backpacking frames

- Ballistic plates

- Bottle caps

- Chemical resistant piping systems

- Coax cable inner insulator

- Food storage containers

- Fuel tanks for vehicles

- Corrosion protection for steel pipelines

- Electrical and plumbing boxes

- Far-IR lenses

- Folding chairs and tables

- Geomembrane for hydraulic applications (such as canals and bank reinforcements) and chemical containment

- Geothermal heat transfer piping systems

- Heat-resistant fireworks mortars

- Hard hats

- Hula hoops

- Natural gas distribution pipe systems

- Plastic bags

- Plastic bottles suitable both for recycling (such as milk jugs) or re-use

- Plastic lumber

- Plastic surgery (skeletal and facial reconstruction)

- Root barrier

- Snowboard rails and boxes

- Storage sheds

- Telecom ducts

- Tyvek

- Water pipes for domestic water supply and agricultural processes

- Wood plastic composites (utilizing recycled polymers)

HDPE Plastic Code

Thursday, March 14, 2013

Polyethylene terephthalate (PETE) and uses

Polyethylene terephthalate commonly abbreviated PET, PETE, or the obsolete PETP or PET-P, is a thermoplastic polymer resin of the polyester family and is used in synthetic fibers; beverage, food and other liquid containers; thermoforming applications; and engineering resins often in combination with glass fiber. The term polyethylene terephthalate is a source of confusion because this substance, PET, does not contain polyethylene. Thus, the alternate form, poly(ethylene terephthalate), is often used in scholarly journals for the sake of accuracy and clarity.

Depending on its processing and thermal history, polyethylene terephthalate probably as an amorphous (transparent) and as a semi-crystalline polymer.Semicrystalline material might appear transparent (particle size < 500 nm) or opaque and white (particle size up to a few microns) depending on its crystal structure and particle size. Its monomer (bis-β-hydroxyterephthalate) can be synthesized by the esterification reaction between terephthalic acid and ethylene glycol with water as a byproduct, or by transesterification reaction between ethylene glycol and dimethyl terephthalate with methanol as a byproduct. Polymerization is through a polycondensation reaction of the monomers (done immediately after esterification/transesterification) with water as the byproduct.

The majority of the world's PET production is for synthetic fibers (more than 60%), with bottle production accounting for around 30% of global demand. In the context of textile applications, PET is referred to by its common name, "polyester," whereas the acronym "PET" is generally used in relation to packaging. Polyester makes up about 18% of world polymer production and is the third-most-produced polymer; polyethylene (PE) and polypropylene (PP) are first and second, respectively.

PET is an excellent barrier material, plastic bottles made from PET are widely used for soft drinks. For certain specialty bottles, PET sandwiches an additional polyvinyl alcohol layer to reduce its oxygen permeability.Biaxially oriented PET film it can be aluminized by evaporating a thin film of metal onto it to reduce its permeability, and to make it reflective and opaque (MPET). These properties are useful in many applications, including flexible food packaging and thermal insulation such as "space blankets". Because of its high mechanical strength, PET film is often used in tape applications, such as the carrier for magnetic tape or backing for pressure sensitive adhesive tapes.

Non-oriented PET sheet can be thermoformed to make packaging trays and blisters. If crystallizable PET is used, the trays can be used for frozen dinners, since they withstand both freezing and oven baking temperatures.When filled with glass particles or fibers, it becomes significantly stiffer and more durable.PET is also used as substrate in thin film and solar cell.

Picture of PETE product

Depending on its processing and thermal history, polyethylene terephthalate probably as an amorphous (transparent) and as a semi-crystalline polymer.Semicrystalline material might appear transparent (particle size < 500 nm) or opaque and white (particle size up to a few microns) depending on its crystal structure and particle size. Its monomer (bis-β-hydroxyterephthalate) can be synthesized by the esterification reaction between terephthalic acid and ethylene glycol with water as a byproduct, or by transesterification reaction between ethylene glycol and dimethyl terephthalate with methanol as a byproduct. Polymerization is through a polycondensation reaction of the monomers (done immediately after esterification/transesterification) with water as the byproduct.

The majority of the world's PET production is for synthetic fibers (more than 60%), with bottle production accounting for around 30% of global demand. In the context of textile applications, PET is referred to by its common name, "polyester," whereas the acronym "PET" is generally used in relation to packaging. Polyester makes up about 18% of world polymer production and is the third-most-produced polymer; polyethylene (PE) and polypropylene (PP) are first and second, respectively.

PET is an excellent barrier material, plastic bottles made from PET are widely used for soft drinks. For certain specialty bottles, PET sandwiches an additional polyvinyl alcohol layer to reduce its oxygen permeability.Biaxially oriented PET film it can be aluminized by evaporating a thin film of metal onto it to reduce its permeability, and to make it reflective and opaque (MPET). These properties are useful in many applications, including flexible food packaging and thermal insulation such as "space blankets". Because of its high mechanical strength, PET film is often used in tape applications, such as the carrier for magnetic tape or backing for pressure sensitive adhesive tapes.

Non-oriented PET sheet can be thermoformed to make packaging trays and blisters. If crystallizable PET is used, the trays can be used for frozen dinners, since they withstand both freezing and oven baking temperatures.When filled with glass particles or fibers, it becomes significantly stiffer and more durable.PET is also used as substrate in thin film and solar cell.

Picture of PETE product

Thursday, March 7, 2013

Production of plastics, Incineration of plastics, Pyrolytic disposal

Plastic production of crude oil requires 62-108 MJ of energy per kilogram.While Producing silicon and semiconductors for modern electronic equipment is even more energy consuming: 230 to 235 MJ per 1 kilogram of silicon, and about 3,000 MJ per kilogram of semiconductors. This is much higher, compared to many other materials, e.g. production of iron from iron ore requires 20-25 MJ of energy, glass (from sand, etc.) - 18-35 MJ, steel (from iron) - 20-50 MJ, paper (from timber) - 25-50 MJ per kilogram.

Controlled high-temperature incineration, above 850C for two seconds, performed with selective additional heating, breaks down toxic dioxins and furans from burning plastic, and is widely used in municipal solid waste incineration. Municipal solid waste incinerators also normally include flue gas treatments to reduce pollutants further. This is needed because uncontrolled incineration of plastics produce carcinogenic polychlorinated dibenzo-p-dioxins, a cancer causing chemical. The problem occurs as the heat content of the waste stream varies. Open-air burning of plastic occurs at lower temperatures, and normally releases such toxic fumes.

Plastics can be pyrolyzed into hydrocarbon fuels, since plastics have hydrogen and carbon. One kilogram of waste plastic produces roughly a liter of hydrocarbon.

This picture is place of incineration

This picture is process of incineration

Controlled high-temperature incineration, above 850C for two seconds, performed with selective additional heating, breaks down toxic dioxins and furans from burning plastic, and is widely used in municipal solid waste incineration. Municipal solid waste incinerators also normally include flue gas treatments to reduce pollutants further. This is needed because uncontrolled incineration of plastics produce carcinogenic polychlorinated dibenzo-p-dioxins, a cancer causing chemical. The problem occurs as the heat content of the waste stream varies. Open-air burning of plastic occurs at lower temperatures, and normally releases such toxic fumes.

Plastics can be pyrolyzed into hydrocarbon fuels, since plastics have hydrogen and carbon. One kilogram of waste plastic produces roughly a liter of hydrocarbon.

This picture is place of incineration

This picture is process of incineration

Tuesday, February 26, 2013

Nylon

Nylon was the first purely synthetic fiber, introduced by DuPont Corporation at the 1939 World's Fair in New York City. In 1927, DuPont Corporation had begun a secret development project name Fiber66. Wallace Carothers the Harvard Chemist and Elmer Keiser Bolton is the department chemist as director. Carothers was hired to perform pure research, he worked to understand the new materials molecular structure and physical characters.

And he was found synthetic nylon fiber, which was very strong and also very flexible. The first application was for bristles toothbrushes. However, Du Pont's real target was silk, particularly silk stockings. It took DuPont twelve years and US$27 million to refine nylon, to synthesize and develop the industrial processes for bulk manufacture. With a major investment, it wasn't surprise that Du Pont spared little expense to promote nylon after its introduction, creating a public sensation, or "nylon mania".

Nylon was stop at the end 1941 because of America had World War II. After 1946 DuPont Corporation was promote Nylon again to public .Nylons still important plastics, and not just for use in fabrics. In its bulk form it is very wear resistant, particularly if oil-impregnated, and it used to build gears, plain bearings, valve seats, seals and because of good heat-resistance, increasingly for under-the-hood applications in cars, and other mechanical parts.

And he was found synthetic nylon fiber, which was very strong and also very flexible. The first application was for bristles toothbrushes. However, Du Pont's real target was silk, particularly silk stockings. It took DuPont twelve years and US$27 million to refine nylon, to synthesize and develop the industrial processes for bulk manufacture. With a major investment, it wasn't surprise that Du Pont spared little expense to promote nylon after its introduction, creating a public sensation, or "nylon mania".

Nylon was stop at the end 1941 because of America had World War II. After 1946 DuPont Corporation was promote Nylon again to public .Nylons still important plastics, and not just for use in fabrics. In its bulk form it is very wear resistant, particularly if oil-impregnated, and it used to build gears, plain bearings, valve seats, seals and because of good heat-resistance, increasingly for under-the-hood applications in cars, and other mechanical parts.

Picture of Wallace Carothers

Picture of Elmer Keiser Bolton

Friday, February 1, 2013

Polyvinyl chloride

Polyvinyl chloride, commonly abbreviated PVC, is the third-most widely produced plastic, after polyethylene and polypropylene. PVC or Polyvinyl chloride has a stiff resistance properties, strong, heat and weather, the nature of the recommended use for pipes, ditches, walls, enclosures for computers and other electronic equipment. PVC can also be softened through a chemical process, and at the present time can be used in the form of shrink-wrap, food packaging, and rain gear (raincoats).

form Pure polyvinyl chloride is a white, brittle solid. this things insoluble in alcohol, but slightly soluble in tetrahydrofuran.

In 1835 PVC was found by French chemist Henri Victor Regnault and then in 1872 by German chemist Eugen Baumann.

form Pure polyvinyl chloride is a white, brittle solid. this things insoluble in alcohol, but slightly soluble in tetrahydrofuran.

In 1835 PVC was found by French chemist Henri Victor Regnault and then in 1872 by German chemist Eugen Baumann.

Eugen Baumann German Chemist

Henri Victor Regnault France Chemist

The relatively low cost PVC been tested either through biological and chemical processes that lead to PVC pipes are used for disposal of waste, door frames, wire insulators, etc.

Pipe

Pipes, which are lightweight, low maintenance costs can be accounted for 66% in the American market are usually planted in the ground and used as a waste dump, the distribution of clean water.

Electric Cables

PVC uses the electrical wiring is a good barrier to prevent sparks that shorted can be minimized.

Sign

Polyvinyl chloride is formed from a flat sheet with a variety of shapes and colors. usually in the form of lines of the car body.

Clothing and furniture

PVC has been used as well as clothes to replace materials such as leather, rubber, and latex. Besides pvc also waterproof so can be used for coats, ski equipment, jackets, aprons, and bags.

Medical Equipment

One-third of the medical equipment is made of PVC for example scissors, knives, cutter, clamp, blood bags, etc.

Flooring

PVC can be used as flooring because besides cheap, shiny and easy maintenance suitable for homes, hospitals, offices, schools, etc.

Other Apllications

PVC can be used on kids toys, interior clauding, custom truck troppers, green house, kids play ground, etc.

Monday, January 7, 2013

Polystyrene

Polystyrene is a plastic used to knick knacks and toy in the current period. The plastic is stiff and brittle and made of styrofoam.

In 1839 by Eduard Simon discovered polystyrene. Polystyrene found from Turkish Sweetgum Liquidambar tree oriental.

Polyestyrene plastic is resistant to acid and alkali are so many uses for example stereofoam made to put the food. Use plastic thermoforming and injection molding method is used to produce disposable spoon and fork, a diamond, a smoke detector, plates for cars, and others.

Polystyrene foam is a good insulator to be used for isolation of building materials such as concrete, and also has good damping properties to the plastic used for packaging.

Polystyrene foam is poison for life in the ocean when eaten by a bird or sea creature excessively.

Ways to minimize consumption polystyrene is made by Starbuck coffee cup could replace recyclable.

Product of polystyrene

Subscribe to:

Comments (Atom)